Configuration options

Configurations options for a proper steel hall from Husen

Whether it is for the industry, trade, commerce or service sector, whether it is production halls, warehouses, exhibition halls or sports halls – there is one thing that original Husen-halls always have in common: maximum quality. Both in terms of materials as well as design and assembling.

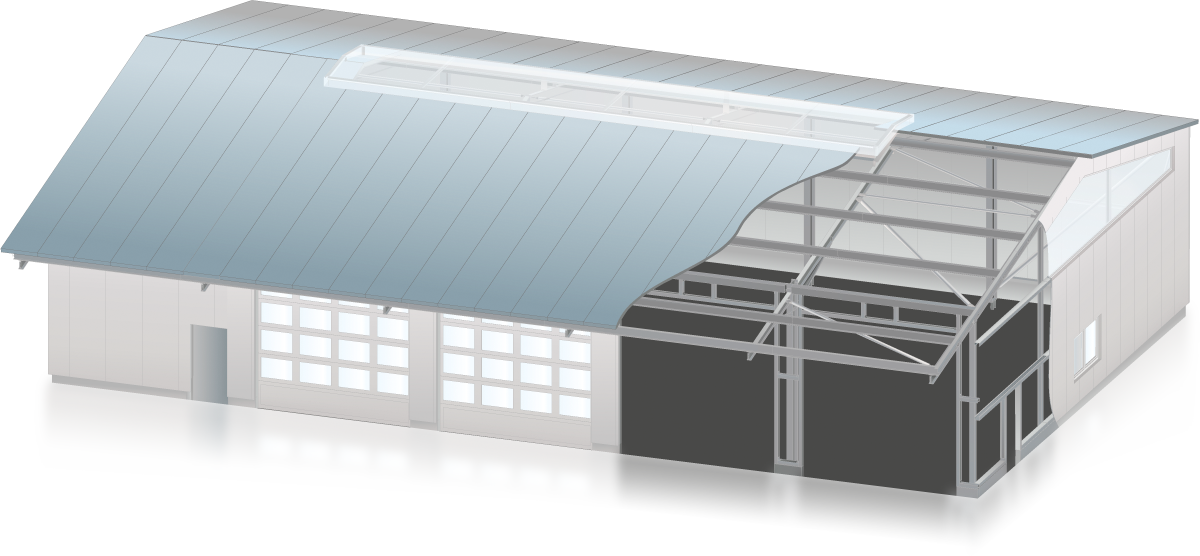

You can find out how this is reflected in detail and what configuration options you have by clicking on the information boxes in the cross section of the hall below.

1. MAIN CONSTRUCTION WITH WIND BRACING AND CANOPY

Hall support structure in welded and screwed design. Consisting of steel profiles, meeting static requirements, in hot dip galvanized or coated design.

3. WALL SUPPORTING STRUCTURE

Layer of galvanized C sections as supporting of the wall cladding and as substructure of the gates, doors and windows.

5. VERGE

Profiled and colour coated flat steel sheet at the edge of the roofing on both gable walls.

6. RAIN BAFFLE SHEET

Edge profiled and colour coated flat steel sheet as water repellent edge component on both sides of the eaves.

7. RIDGE COVERING

Ridge cover plate consisting of edge profiled and colour coated steel sheets. Depending on the roof design with a simple or double ridge plate (with internal thermal insultation).

9. WALL COVERING

Façade design, according to requirements, in single skin or insulated design; surface and colour as requested.

10. CORNER ANGLES

Covers of the hall’s angles consisting of edge profiled and colour coated flat steel sheets.

11. DRIP EDGE

Edge profiled and colour coated flat steel sheet to handle the water; above gates, doors, windows and plinth.

12. GATE, DOOR AND WINDOW SURROUND

Surround of the gate, door and window reveal consisting of edge profiled and colour coated flat steel sheets.

13. WINDOW WITH WINDOW SILL

Placing of plastic or aluminium window elements; colour and design as requested.

16. RIDGE STRIP-LINE LIGHT WITH OPTIONAL VENT

Strip-line light on the ridge for better illumination in the hall, optionally with ventilation installation or vent.

17. INSULATED STRIP-LINE LIGHT FRAME EDGING

Surround of the frame of the strip-line light consisting of edge profiled steel sheets and internal thermal insulation.

18. INSULATED ALUMINIUM HEAD

Edge profiled flat aluminium sheets covering the ends of the strip-line light, including fitting thermal insulation.